In Japan there’s a saying that you’re a fool if you never climb Mt Fuji and that you’re also a fool if you climb it more than once. As an old admirer of Mt Fuji who has just climbed it for the first time, I can now also understand the second half of the saying. I thought I was reasonably fit, but hiking up there with my level of training was one of the most foolish things I have ever done. Never before in my live had I felt so exhausted as during the last kilometers on the way down to the bus stop at the Subashiri 5th stage.

Since first coming to Japan as a visitor more than two decades ago, I have always loved the majestic views that Mt. Fuji offers, especially how its often snow-capped cone shape pops up unexpected, often from far away. Its views are particularly clear during the dry winter season. The furthest I’ve seen it from was from a bus on the expressway near Narita airport, about 160 km east of the mountain. My favourite views are from around Izu peninsula in Shizuoka. I’d been up on the 5th stage several time, the highest you go by car or bus (or bicycle).

My friend Tom did a double traversal of the Grand Canyon (South rim – bottom – North Rim – bottom – South rim) with several friends on his 40th birthday and climbed Mount Kilimanjaro (5895m) the year he turned 50. That impressed me so much that I promised myself I would climb Mt Fuji the summer of the year I turned 40. That didn’t happen. But 10 years later I was determined to make it up there as a 50 year old. Last weekend I finally did it.

My preparation included one hike of a few hours with my family along the coast near Izu Kogen and a 2 hour hike up a mountain in Saitama prefecture with my son, es well as some bike rides for general fitness. It was nowhere near enough. My legs were not used to descending much and my maximum distance was far too short. It was like trying to run a marathon after only ever having run a maximum of 5 km.

I wore my hiking boots and dressed in enough layers appropriate for temperatures a little above freezing. Temperatures at the peak are roughly 20C (36F) lower than at sea level. I brought a wool cap, gloves and a headlamp for nighttime hiking. I took food and a several liters of water in my backpack. I probably would have managed with 2 liters, but took more, which ended up being on the heavy side.

We took a highway bus from Tokyo Shinjuku to Gotemba and from there shared a cab to the Fujinomiya 5th stage on the south side of the mountain. We had breakfast there and put on our rain gear, taking our time to give the body a chance to acclimatize a bit to the altude (~2400m / 8000 ft = 24% less oxygen). The hike up to the 9th stage mountain hut was mostly in fog and drizzle, unfortunately. As you climb up higher, the vegetation gets more and more sparse until it feels like you’re on another planet. Some of the volcanic rock is very colourful.

Along the trail from the 5th stage parking lot to the peak there are four mountain huts, the 6th trough 9th stages (roku-go-me through kyu-go-me in Japanese). They provide food, toilets and accommodations during the climbing season. Most seem to run diesel generators to generate their own power, as they are not connected to the grid. If you’re an NTT docomo customer you can also get mobile reception there.

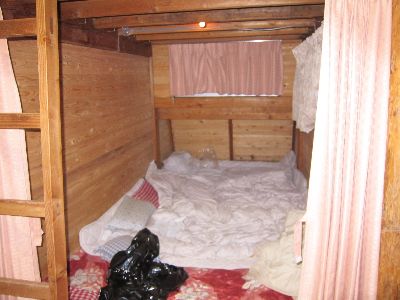

We had reservations at the 9th stage hut, which is one of the largest, but this being the last weekend of the annual climbing season, as many hikers as possible were crammed into the tiny rooms. We were seven guys in one 5 m2 (54 sqft) room (1.8 m by 2.7 m / 6 ft by 9 ft, three tatami mat size). A small light bulb stayed on all night and there were people snoring loudly all over. The rooms were on two levels, with ladders to the top ones, all separated from the corridor by a curtain. The air at 3460m above sea level already has 34% less oxygen, but the large number of hikers in a small space must have dropped it even further, resulting all of our group having headaches, a symptom of altitude sickness.

It is very common for Fuji hikers to carry oxygen cans (5l for about 500 yen) to inhale when they feel weak. Like many gaijin (foreigners) I first laughed about this, but when not feeling well I gave it a try. I can’t say it really made that much difference for me. I think the act of stopping to get out the can, fit the inhaler, take a couple of breaths and stash it away again provided as much rest that it was hard to tell if one feels better because of the rest or because of the short term oxygen boost. Himalaya climbers on oxygen breathe it for extended periods, so its effects are not really comparable.

There were people hiking past the hut all night. You could see a line of what looked like fireflies in the distance slowly moving up the huge dark cone of the mountain towards us, and up above us, towards the peak. In the afternoon the sky had cleared up and we could enjoy the views of clouds below us, like from an airplane. At night the sky was full of stars, like in my village at home but unlike the big cities in Japan, where the glare of street lights all but obscures the nighttime sky and where people never see the Milky Way.

The mountain hut gradually got busy after midnight, as hikers got ready to set off for the peak to experience the sunrise from the top. Lacking in sleep, we rested longer and left around 5 am, seeing the sunrise to the East from the Southern slope about 1 km from the peak.

The last few hundred meters below the tori (Shinto shrine gate) that marks the entrance to the crater rim were mostly spent waiting in a queue, for hundreds of ascending and descending hikers to pass each other on the narrow trail. As we got closer we could also smell the public toilets. At the top there was the shrine and next to it Japan’s highest Post office for sending cards with a Mt Fuji post mark to your friends.

By the time we were at the peak, I had pretty much run out of gas, probably not helped by the lack of sleep under cramped conditions the night before. The hike around the crater rim, up to the weather station located on the highest point (3776m / 12388 ft) and over to the opposite side was difficult already.The crater was very deep and huge. You saw many layers of rock exposed and could only marvel at the force of the explosions that dug it into the top of the mountain. Both inside the crater and at some spots along the slope outside we still found white snow in August.

Our return route was via the Subashiri trail, which is famous for very loose sandy slopes that some people find convenient for sliding down almost like skiing, supposedly making it a very fast return route. For me this was the hardest part of the trip, already lacking the muscle strength to have the kind of control to master sliding. I ended up walking most of it, with the effect of hardly being able to walk down any stairs when I got home. I recovered after three days.

The 5th stage on the Subashiri trail lies lower (about 2000m) than the other trails. The last part of the trail is through forest. That makes it more interesting to hike when you ascend there. It’s less steep but longer than other trails.

Call me a fool (as per the Japanese saying I quoted at the start), but I definitely want to go back to Mt Fuji next year. I want to climb it again, but with better training upfront and I’ll have nice experiences to add to the strong memories from the first climb. I am also interested into climbing up to the 5th stage by bicycle, as I am just getting myself a Bike Friday Pocket Rocket for trips into the countryside.